LENTICULAR PRINTING

Lenticular is a specialty printing process that layers an interlaced image with a lenticular lens sheet to produce prints that appear 3D or animated as you view them from different angles. The technique has been used to create illusions in printed items like postcards, posters and collectibles since the 1940s and has a dedicated fanbase of artists and collectors drawn to its interactive nature. Lenticular delivers something unique and magical and consequentially its not always obvious how the illusion relates to the underlying process. If you have ever wanted to peek behind the curtain or make your own lenticulars then this guide is for you!

Looking to make lenticular prints? Explore our custom lenticular printing services.

History of Lenticular Printing

Lenticular printing has roots reaching back into the early 20th century, but the technology truly began to gain traction in the 1940s through the efforts of the company Vari-Vue. They were the first company to truly capture the public's imagination through mass-produced novelty items - collectible pins, postcards, and promotional giveaways featuring simple flip effects and animations. Others quickly saw the opportunity and lenticular fully entered its kitsch phase with an expanded pallet of themes including 3D pinup girls, religious devotional material and children’s storybook illustrations. While this remains an especially collectable and fun era it had an oversize effect in the perception of the medium and left a lingering impression of lenticular as a non-serious process for art making.

It wasn't until Israeli-French kinetic artist Yaacov Agam began incorporating lenticular processes into his work in the late 1950s that the medium saw its first obvious artistic exploration. Agam recognized lenticular's potential for creating transformative, participatory artwork and produced a substantial body of work where lenticular was an important component. Agam’s interests were in movement, interaction and perception, not imagery, and this break from lenticular’s traditional use helped it move beyond its novelty origins.

The music industry has embraced the medium since the Rolling Stones pioneered the lenticular album cover with Their Satanic Majesties Request in 1967, a tradition continued today by artists seeking to create special editions and collector's items, like our recent project with the Osees.

The period of mass adoption, both commercially and artistically, arrived with the digital revolution of the 1990s. The introduction of large format inkjet printers, combined with manufacturing capabilities from companies like Microlens and Topan, suddenly made large-scale lenticular sheets both feasible and affordable. This convergence of technology opened doors for advertisers seeking dynamic campaigns and artists exploring new forms of visual expression.

Contemporary LENTICULAR

Despite its engaging nature the added production costs have kept lenticular primarily as a specialty product. Large brands tend to use more lenticular than smaller companies, and it is often associated with important product launches and projects.

Out-of-home placements are one increasingly common location to find commercial lenticulars. Transit-shelter kiosks work well for large format lenticular prints because pedestrian flow continually changes the view and keeps the image active. Subway stations provide a similar audience and energy as seen in this project for the series The Walking Dead.

At larger scales, multi-panel tiled installations have become increasingly common. Innovative methods for aligning individual sheets together to maintain synchronicity allow an entire wall of lenticular imagery to move in unison. Tiled lenticulars appear in airports, trade shows, and university settings, including these installations for Highpoint University and ET Global Exhibit Group.

Lenticulars end up making appearances in unexpected places too. Take for example this project for the San Francisco Museum of Modern Art featuring an exhibition on Photography and the Art of Mistakes where the exhibition title fades into the wall color as you walk by. Or this project for the Netflix series Maniac where Jonah Hill’s character views a lenticular advertisement on the train.

LENTICULAR IN THE ARTS

The use of lenticular among artists has increased significantly in the last 20 years and while not commonplace lenticular pieces show up more often in gallery shows and fairs than ever before. Artists who carve out a niche in the medium find the field is comparatively open with lots of room to explore. Notable projects by people like Jeff Robb, Chris Dean, Stefan Sagmeister, Nick Cave, Areca Rowe, Margeaux Walter and Mungo Thompson show some of the possibility of lenticular used in non commercial ways. These artists have discovered distinctive ways of working, each exploring particular aspects of lenticular's unique visual language.

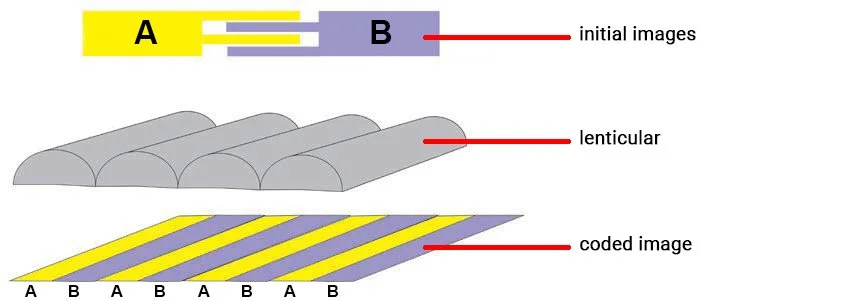

LENTICULAR INTERLACING

The process of preparing source images for lenticular is called interlacing. Viewed on its own interlaces will look like a chaotic array of vertical bands or images with an especially fuzzy depth of field. The slices of images are sequenced in such a way that when they are filtered by the lenticular sheet a predictable experience of motion or depth is experienced. The particulars used in determining how the lenticular works include things like the viewing angle of the lenticular lens and the anticipated viewing distance of the average viewer. Interlaces can be made directly in a program like photoshop but are often produced in specialty software for their fine tuned features.

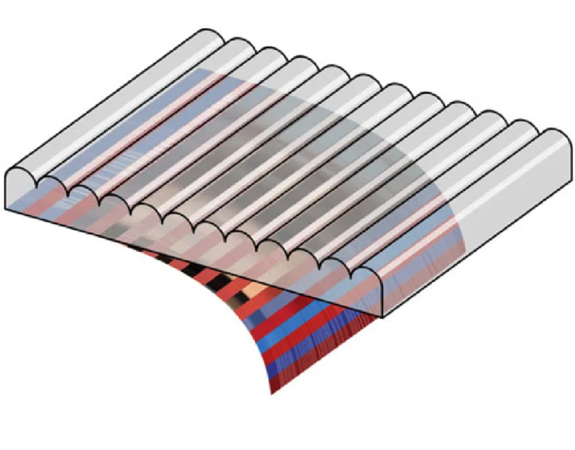

The lenticular sheet

The lens sheet contains hundreds of parallel cylindrical lenses called lenticules, each directing light from specific image strips to your eyes based on viewing angle. When you move different strips become visible through each lens - creating the illusion of dimension or motion. Lenticular sheets are made by heating and extruding plastic resin between large metal cylinders. A pattern is produced on the top side of the sheet that, along with the thickness of the lens, determines the optical properties such as its LPI and viewing angle. These characteristics are using by the interlacing software to create a composite image targeting a particular effect.

LENTICULAR PLASTICS

Lenticular plastic sheets, commonly referred to simply as “lens,” come in three basic material types, PETG, Acrylic and Polystyrene. The majority of lenticular lens used for animation is PETG, a form of polyester which is very durable and long lasting. It is resistant to impact fractures and cracking and is a great choice for both fine art and commercial lenticular.

Acrylic (PMMA) is a very common everyday sheet plastic and some very high quality lenticular lenses have been made from acrylic resin. Acrylic is known for its clarity, especially when used in thicker sheet products, and can be used outside.

Polystyrene, or PS, is a clear plastic resin suitable for thick sheet products and the most common material for 3D lens. It clarity makes it a good choice for heaver gauge materials though its impact sensitivity requires greater care in handling.

LENTICULES PER INCH (LPI)

Perhaps the best known feature of a lenticular lens is its resolution which is measured in ‘lenticules’ per inch or LPI. The LPI of a lens can be very coarse or fine which is an indication of its intended viewing distance. Large format lenticular typically uses lenses in the 15 LPI - 40 LPI range. LPI represents one of the first tradeoffs that are considered when making a lenticular print. Coarser lenses hide neighboring images better to lessen “ghosting” between frames and offer greater viewing distances with more precision. Finer lenses excel because their surface structure can completely disappear when viewed from several feet, making them a good choice when there is a lot of fine detail. But there are no strict rules with LPI, large pieces are often very effectively printed on fine lenses - it depends on how the artwork is set up and the expectations of the designer.

Viewing Angle

Lenticular sheets are engineered with a particular viewing angle with typical ranges from 25 to 54 degrees. Lenses with narrow viewing angles are usually meant for 3D and wider for motion, but both effects can be achieved with lenses of any viewing angle with varied results. The most apparent result of the viewing angle is how quickly the lenticular flips, with narrow viewing angles producing quick flipping imagery and a wider angle producing slower flips. The viewing angle also determines how many times the image sequence will repeat, for example a 3 image sequence will repeat 4 times using a 45 degree lens but 7 times using a 25 degree lens.

Viewing Distance

Lenticular lens has limits in terms of how effective it is at various distances. In general the same considerations given to LPI apply here, with fine LPI lenses having shorter viewing distances (1-10 ft) and coarser lenses being more suitable for distance viewing (5-30 ft). The effectiveness of a lenticular print beyond 30 ft is variable and the amount of movement required to engage the effect can become a deterrent to lenticulars with exceptionally long viewing distances.

LARGE FORMAT LENTICULAR PRINTING

Large format lenticular prints are made not on specialty machines but instead on printers designed for high quality printing on regular surfaces, whether that is paper, film or directly to the lenticular lens itself. Factors such as resolution, accuracy of ink drop placement and longevity of prints are the considerations that most influence the machine used. Those making lenticular prints at home or in small production environments often use roll based printers because of the size and practicality while its common to use UV flatbed presses when direct printing to large sheets or volume is required. Because lenticular printing has unique alignment requirements and is prone to artifacts that only become visible when viewed through the lenticular sheet, technicians must adapt general-use machines and software through various modifications and specialized workflows. These customized approaches contribute to the mystique of the process, adding another dimension of complexity to an already unconventional medium.