WHAT IS LENTICULAR PRINTING?

The Science Behind the Magic

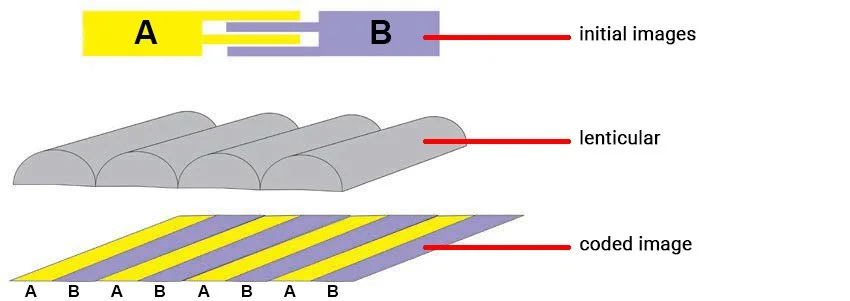

Lenticular printing works by layering two distinct technologies: an optical lens sheet and a specially prepared image. The lens sheet contains hundreds of parallel cylindrical lenses - lenticules - each directing light from specific image strips to your eyes based on viewing angle. When you move, different strips become visible through each lens, creating the illusion of motion or transformation.

The process starts with taking multiple images or frames and slicing them into thin vertical strips. These strips are then interlaced - woven together in precise sequence - and printed at exact resolution to match the lens sheet above. The alignment must be perfect: each lenticule corresponds to a specific set of image strips beneath it. Move your head slightly, and the angle of light refraction changes, revealing the next strip in the sequence.

Lenticular is purely mechanical, requiring no power source and no digital components. While lenticular has a patently modern allure, it relies on the same principles developed in the 20th century: controlled light refraction through engineered plastic surfaces. The tolerances required during the lenticular printing process are extreme, requiring microscopic precision, but the physics are straightforward. Light hits each cylindrical lens, bends according to your viewing angle, and illuminates only one image strip at a time.

Variations in the design of the lenticular materials allow the process to be used to create multiple engaging effects. When engineers change the thickness of the lens sheets, the viewing angle of the individual lenticules and other physical properties, lenticular can be used to create multiple different effects, from autostereoscopic 3D to multi-frame animation.

Lenticular’s Roots

Lenticular printing has roots early into the 20th century but really began to gain traction in the 1950s. Primarily used to create novelty items like pins and postcards, and then later pin-ups and religious themed posters, it wasn’t until kinetic artist Yacov Agam began using the process in his work that lenticular saw an interesting non-commercial exploration. The next wave of artistic adoption coincided with the commercial success of the large format inkjet printer in the 1990s which allowed people to use digital tools instead of photographic processes to explore the process.

3D Lenticular

One of the most curious qualities of lenticular printing is the ability to portray an illusionary sense of depth. Careful optical engineering combined with precise graphics send visual information to our left and right eyes in a way that mirrors our natural stereo vision. Slight variations in the underlying imagery give the illusion of dimensionality and we perceive the scene in front of us as being something more than a flat surface. This effect has been used on album covers, xxx and xxx, found xxx and also xxx.

Motion Lenticular - Animation and Flip

Lenticular printing also has the ability to create imagery that flips, morphs and animates as viewers interact with it. The same optical engineering, tweaked for motion, produces a surface that is

Types of Materials

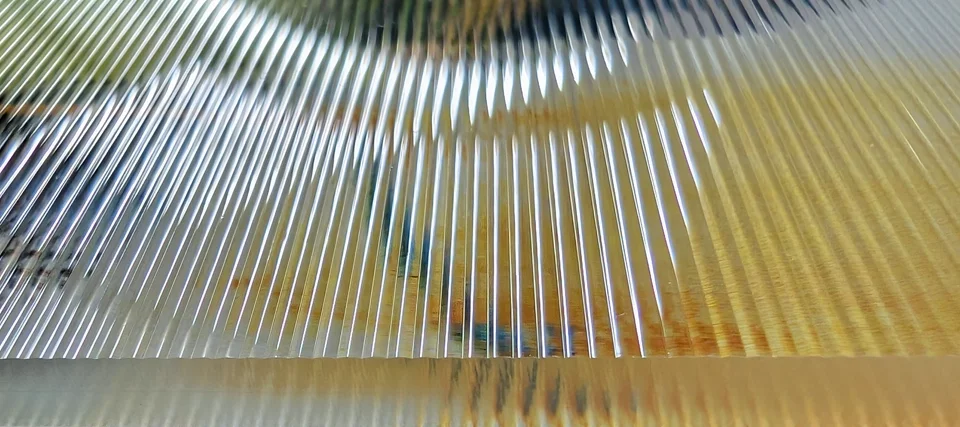

Lenticular’s early materials were composites of glass, plastics and resins and because they often relied on photographic production were limited to smaller size sheets. Todays lenticular materials are exclusively plastic and come in sizes up to 4x8’.

Lenticular plastic sheets, commonly referred to simply as “lens,” come in three basic material types, PETG, Acrylic and Polystyrene. The majority of lenticular lens used in the United States and Europe is PETG, a form of polyester which is very durable and long lasting. It is resistant to impact fractures and cracking and is a great choice for both fine art and commercial lenticular.

Acrylic (PMMA) is a very common everyday sheet plastic and some very high quality lenticular lenses have been made from acrylic resin. Acrylic is known for its clarity, especially when used in thicker sheet products, and can be used outside.

Polystyrene, or PS, is a clear plastic resin suitable for thick sheet products and the most common material for 3D lens. It clarity makes it a good choice for heaver gauge materials though its impact sensitivity requires greater care in handling.

LPI

Perhaps the best known feature of a lenticular lens is its resolution which is measured in ‘lenticules’ per inch or LPI. The LPI of a lens can be very coarse or fine which is an indication of its intended viewing distance. Large format lenticular typically uses lenses in the 15 LPI - 40 LPI range. LPI represents one of the first tradeoffs that are considered when making a lenticular print. Coarser lenses hide neighboring images better to lessen “ghosting” between frames and offer greater viewing distances with more precision. Finer lenses excel because their surface structure can completely disappear when viewed from several feet, making them a good choice when there is a lot of fine detail. But there are no strict rules with LPI, large pieces are often very effectively printed on fine lenses - it depends on how the artwork is set up and the expectations of the designer.

Thickness

For large format lenticular thickness is a range that goes from .033” to .15” and is typically affected by two factors, the LPI and whether the lens is meant for 3D or motion. 3D lenses are always thicker than motion lenses and lower LPI lenses are often thicker than higher LPI lenses. In many cases the thickness is not important to the end user unless the print must fit into an existing fixture that has certain tolerances. As a general rule large format lenticulars require a display support of some kind to prevent sagging.

Viewing Angle

Lenticular sheets are engineered with a particular viewing angle with typical ranges from 25 to 54 degrees. Lenses with narrow viewing angles are usually meant for 3D and wider for motion, but both effects can be achieved with lenses of any viewing angle with varied results. The most apparent result of the viewing angle is how quickly the lenticular flips, with narrow viewing angles producing quick flipping imagery and a wider angle producing slower flips. The viewing angle also determines how many times the image sequence will repeat, for example a 3 image sequence will repeat 4 times using a 45 degree lens but 7 times using a 25 degree lens.

Viewing Distance

Lenticular lens has limits in terms of how effective it is at various distances. In general the same considerations given to LPI apply here, with fine LPI lenses having shorter viewing distances (1-10 ft) and coarser lenses being more suitable for distance viewing (5-30 ft). The effectiveness of a lenticular print beyond 30 ft is variable and the amount of movement required to engage the effect can become a deterrent to lenticulars with exceptionally long viewing distances.

Printing Process

Once the image sequence has been interlaced it is printed, in our case using a UV flatbed press. This printer produces beautiful, high color-gamut prints using automotive grade inks known for their exceptional fade resistance and durability. Because the interlaced image is printed directly to the lenticular sheet there are no concerns for delamination or problems associated with adhesives. The result is a singular surface that is impervious to moisture and able to withstand even direct exposure to UV light for years without fading.